Increasing cooling tower efficiency plays quite a significant role in improving the overall efficiency of commercial and industrial cooling systems. The cooling tower is an indispensable component of these systems, be it a commercial system intended for an office building or an industrial one for a refinery, and therefore, maintaining and further increasing its efficiency would be quite beneficial if not crucial.

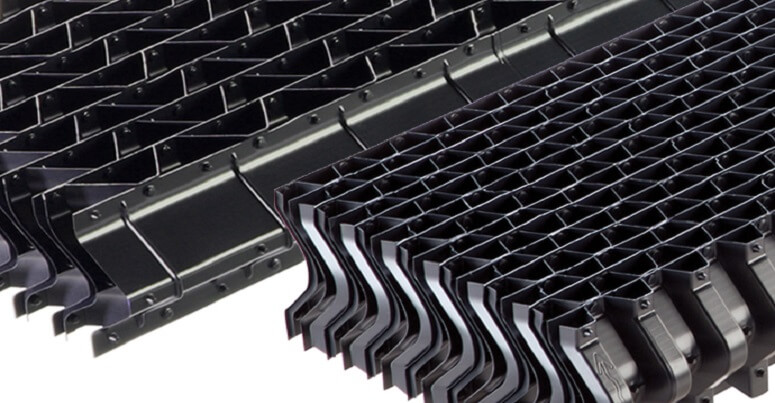

Image from ENEXIO

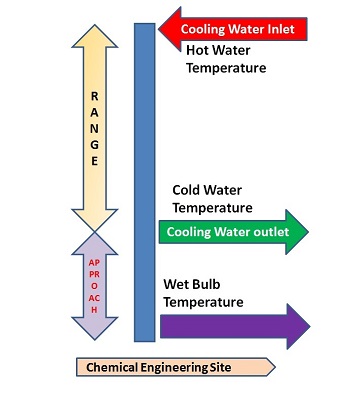

When a cooling tower efficiency is to be designed, some factors are taken into consideration including the wet-bulb

temperature, cooling range, approach to the wet-bulb temperature, water circulation rate, air velocity through the tower's air passageway(s), and of course the tower height. These design parameters will come handy when one is to work around the efficiency of the cooling tower.

Here at Linquip, we have arranged for our clients to conveniently choose from some of the best suppliers of cooling tower parts and products.

Stay tuned for more details about the factors that are for efficiency calculations of the cooling towers.

First Thing to Know about the Cooling Tower Efficiency

There are two factors that are strong indicators of the cooling tower efficiency: makeup water quality and the cycles of concentration (COC). These factors will also help identify whether there is room for improving the efficiency of cooling tower.