Turbines actually act as converters. They convert wind or sea energy into electrical energy and are considered as an alternative to non-renewable resources. There are different types of turbines, such as Impulse Turbine, wind turbine, etc.

Impulse Turbine

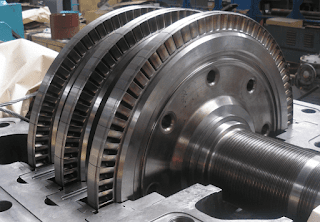

In these turbines, the static pressure inside the runner is constant, and the turbine runner is at atmospheric pressure. The runner spins in the air, and the fluid is sprayed to the blades through the nozzle to exchange energy with the turbine. A jet nozzle or a series of nozzles directs the high-speed flow to the blades, which are usually in the shape of buckets or cups. Therefore, only pressure changes occur in the nozzles.

In the case of steam turbines, such as would be used for marine applications or for land-based electricity generation, a Parsons-type reaction turbine would require approximately double the number of blade rows as a de Laval-type impulse turbine, for the same degree of thermal energy conversion.

Francis Turbine

Francis turbines are primarily used for electrical power production. The power output of the electric generators generally ranges from just a few kilowatts up to 1000 MW, though mini-hydro installations may be lower. The best performance is seen when the head height is between 100–300 metres (330–980 ft).

rancis turbines are employed regularly in hydroelectric power plants. In these power plants, high-pressure water enters the turbine through the snail-shell casing (the volute). This movement decreases the water pressure as it curls through the tube; however, the water’s speed remains unchanged. Following the passing through the volute, the water flows through the guide vanes and is directed towards the runner’s blades at optimum angles.

Kaplan Turbine and Hydrokinetic Turbine

HK turbines have relatively simple designs without the need for a reservoir or spillway. Initial testing indicates the adverse environmental effects are minimal, and the simplicity of these designs results in low-cost installation and maintenance. Therefore, this simplicity makes these systems valuable in rural or remote areas. In the following figure, you can see the flow conditions of hydrokinetic turbines.

A Kaplan turbine is one kind of a propeller hydro turbine (particularly a reaction turbine) used in hydroelectric plants. Waterflow both in and out of Kaplan turbines through its rotational axis, which is called axial flow. The point that makes Kaplan turbines special is that the blades can change their demand to preserve maximum efficiency for various water flow rates.

References:

https://www.linquip.com/blog/hydrokinetic-turbines/

https://www.linquip.com/blog/kaplan-turbine/

https://www.linquip.com/blog/what-is-francis-turbine/

https://www.ethosenergygroup.com/

https://www.linquip.com/blog/impulse-turbine-working-principle/